Enhancing Machine Learning Models in Observational Research with Aivero

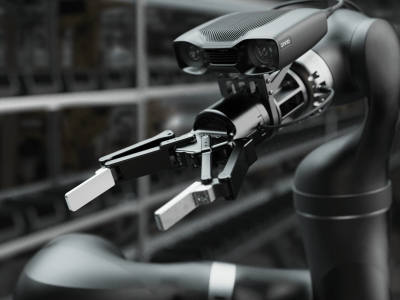

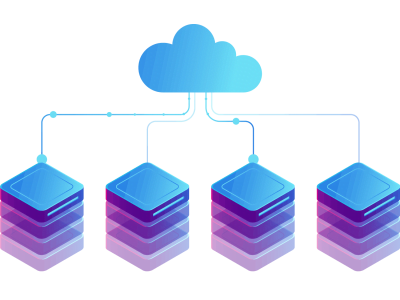

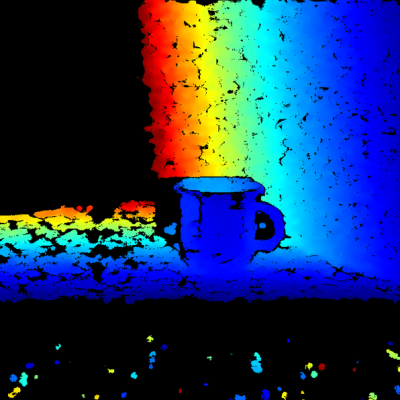

In observational research, the effectiveness of machine learning hinges on the quality of data. As the adage goes, “garbage in, garbage out,” high-quality data is imperative. Aivero transforms this challenge into an opportunity with its versatile software-based platform. Data Quality: The Core of Machine Learning Success Aivero’s platform stands out for its hardware-agnostic capabilities. Whether…